Laser Micromachining

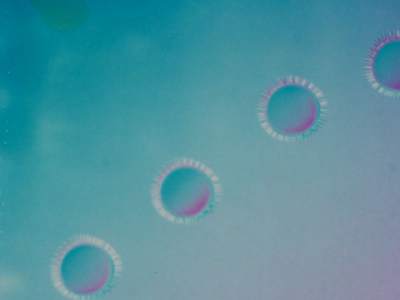

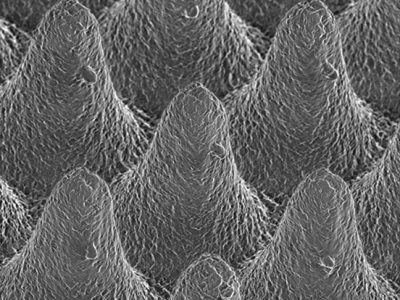

Laser micromachining is of great interest for industrial manufacturing applications as well as for scientific research. The main advantages of the laser as a manufacturing tool are the high speed at which a laser beam can be moved and that laser light is not subject to wear and tear like standard machining tools. Besides the wavelength, the pulse duration of the laser is the main parameter influencing the nature of the laser-material coupling. Pulse durations of down to a few femtoseconds are available from state of the art ultrafast laser systems. The high peak intensities provided by ultrashort pulses initiate multiphoton absorption mechanisms, bridging a band gap much larger than the photon energy. By applying ultrashort pulses the ablation of nearly any material is possible by multiphoton absorption.

Please see our Laser Micromachining application note for additional information.

Laser Micromachining Processes

Application Notes

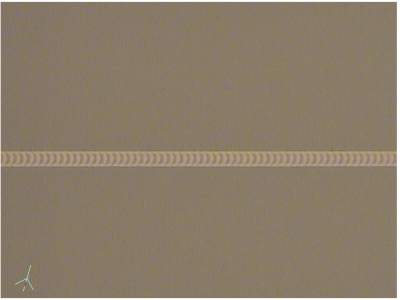

Micromachining Transparent, Brittle Materials

Transparent and/or brittle materials such as glass, ceramics, and crystals are historically difficult to machine with good quality and high throughput. Traditional mechanical processes are often too harsh and, especially for thinner materials, must be slowed down to prevent severe cracking and chipping of the material. In addition, tool wear is problematic because the cutting edges are continually degrading throughout its lifecycle and the quality, yield, etc. of the processed parts are likely to also degrade—this on top of the consumable replacement cost that can be quite high over time. Furthermore, hard brittle materials result in high rates of tool wear and the consumable cost over time can become excessive. Hence, manufacturers have increasingly looked towards laser technology as a solution. Please see Micromachining Transparent, Brittle Materials with IceFyre™ Picosecond Laser for additional information.

Laser Micromachining of Heat-sensitive Polymers

Laser processing of heat sensitive polymers is finding wide use in various manufacturing sectors such as medical device and organic LED manufacturing. For example, heat sensitive, bio-absorbable polymers are increasingly used for production of bio-degradable stents. Because of the low melting temperature (usually below 200° C) of bio-absorbable polymers, any heat load to the surrounding areas during processing should be minimized. Therefore, using femtosecond (fs) pulsed lasers for micromachining of bio-absorbable polymers is highly promising due to the non-thermal nature of laser-material coupling and the possibility of structuring very small, micron-scale features. Please see Laser Micromachining of Heat-sensitive Polymers using a femtosecond, high power and high energy laser for additional information.