Laser Marking and Engraving

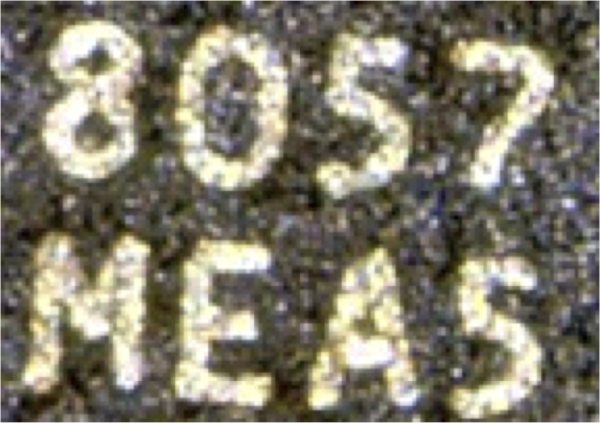

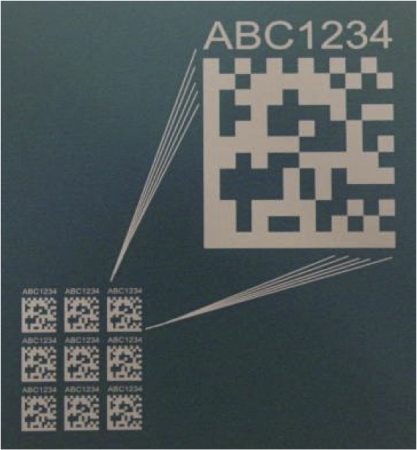

Laser marking is widely used for small-, medium- and large-scale part marking, identification and traceability in a rapid, flexible process. Patterns include texts, 2D barcodes/data matrices, logos, bitmaps or any geometric shape. Spectra-Physics extensive portfolio of Q-Switched, MOPA and CW lasers in IR, green and UV cover a broad range of marking requirements. Combined with compact design and maintenance-free operation, these diverse capabilities make Spectra-Physics’ fiber and DPSS lasers highly attractive for laser marking applications.

Laser engraving provides significant advantages in terms of engraving flexibility, depth, surface finishing and “marking” size. These are some of the key parameters that distinguish laser engraving from alternative engraving or marking technologies. With Spectra-Physics’ VGEN-QS fiber lasers, high-quality and speed engraving can be achieved for various materials – bare and coated metal, ceramics, glass and polymers – and in a broad range of industries such as jewelry, fine art/printing modeling (2D and cylinder), electronics, automotive, and others.

- Deployed in broad range of marking and engraving applications

- Extensive offering: IR, green and UV; Q-switched, MOPA and CW

- High quality, fast and cost-effective solution

- Compact, maintenance-free operation

Laser Marking and Engraving

Laser Marking Trends Toward Shorter Wavelengths

Application examples that are driving the adoption of shorter wavelength lasers:

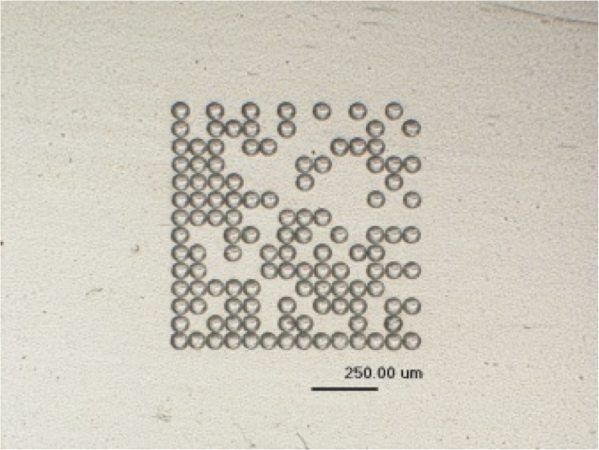

- Reduced feature sizes in 2D-matrix codes

- Medical implants relying on marking technology that avoids material debris

- Mobile device manufacturing require colored layer marking for next generation device covers

- Thin film coatings need nondestructive marking or high quality, narrow line scribing processes

- Plastic materials such as wires, tubes, and composite foils rely on shorter wavelengths for smaller feature size and improved contrast

- UV lasers enable intra-glass or glass surface marking without unwanted heat inclusions

Advantages of UV Laser Marking

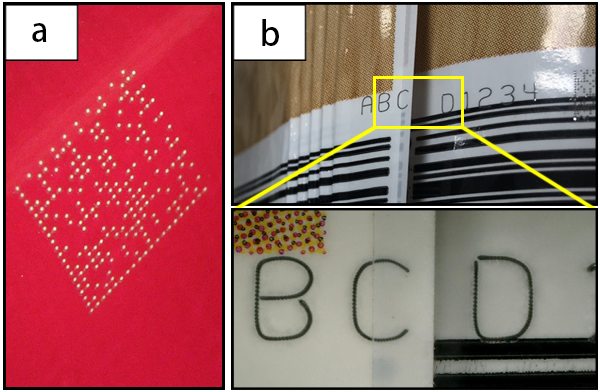

Laser marking of packaging materials is becoming increasingly widespread thanks to its lower operating costs and high flexibility. Due to their relatively low acquisition costs, infrared (IR) lasers (including carbon dioxide lasers) have been used to mark packaging. In many cases, however, these IR lasers cannot achieve the desired marking quality, and ultraviolet (UV) pulsed lasers produce superior results and therefore are the better choice. For instance, some plastic materials exhibit photochemical color change only for UV wavelengths, while with IR lasers marking contrast is poor (Figure 4a). Furthermore, the shallow penetration depth of UV laser light enables marking of thin foils without perforation (Figure 4b). Finally, UV beams are less divergent than IR beams, resulting in a longer Rayleigh range, much larger tolerance to variations in surface topography, and higher process yields (Figures 4c and 4d).

Besides these quality criteria, high process speed is still essential, especially when it comes to marking of packaging material in mass production. High throughput requires not only beam deflection systems with high dynamics, but also lasers which can take advantage of this dynamics by providing sufficiently high pulse energies even at pulse repetition rates of several hundred kHz.

Lasers for Marking and Engraving

Application Notes

Laser Marking Trends Toward Shorter Wavelengths

|

Explorer lasers are equipped with feature rich software capabilities intended to shorten product integration cycles when developing new marking tools or even table top instruments. E-Pulse™ is a very useful feature that provides constant pulse energy over a range of repetition rates and is a great solution when integrating the laser into both gantry and scanner based systems alike.. See Explorer® Fuels Laser Marking Trends Toward Shorter Wavelengths for additional information. |

Marking of Food and Beverage Products

|

The food and beverage industry traditionally uses conventional ink printing to label products with expiration dates and origin information. However, ink cartridges require frequent and costly replacement, and ink can even be harmful to health. Laser marking of packaging materials is becoming increasingly widespread thanks to its lower operating costs and high flexibility. Due to their relatively low acquisition costs, infrared (IR) lasers (including carbon dioxide lasers) have been used to mark packaging. See Marking of Food and Beverage Products in High Throughput Production Lines for additional information. |