Laser Surface Texturing and Patterning

The unique properties of micromachining lasers allow the creation of surface textures and patterns on a wide variety of materials. Novel laser processes allow for the patterning of high-resolution shapes, each with individually tailored surface properties. These unique surface textures and patterns are useful in a wide variety of applications.

- Super-hydrophobic Surfaces

- Super-hydrophilic Surfaces

- High Bonding Strength Surface Textures

Super-Hydrophobic Surface Functionalization

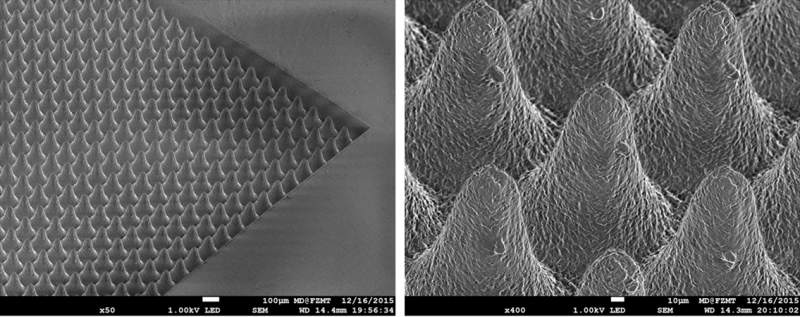

ClearSurface™ is a patent-pending femtosecond laser process for surface functionalization. The novel process allows the patterning of high-resolution shapes, each with individually tailored surface properties. With the new process, the degree of wettability can controlled from super-hydrophobic, or highly water repellant, to super-hydrophilic. Utilizing the widely deployed Spirit® family of industrial femtosecond lasers, ClearSurface enables the fabrication of new medical devices, micro-fluidics, sensors, and other precision parts and devices with controlled and patterned surface properties.

UV Laser Texturing of Carbon Fiber Reinforced Plastic (CFRP)

For adhesive bonding of CFRP, as well as the bonding of paints and protective or functional coatings, a surface preparation process is required. While the primary purpose is to remove residual contaminants from the mold release agent, there can also be the formation of a surface texture which improves its contact (“wetting”, or “wettability”) with the liquid adhesives and coatings.

Using a Quasar® 355-60 laser with TimeShift™ technology, the surfaces of 2 mm thick unidirectional carbon fiber plates can be prepared via a laser irradiation process and subsequently joined effectively with high strength aerospace grade adhesive. Please see UV Laser Texturing of CFRP to Achieve High Bonding Strength for additional information.

Lasers for Surface Texturing and Patterning

Application Notes

UV Laser Texturing of CFRP to Achieve High Bonding Strength

|

The use of Carbon Fiber Reinforced Plastic (CFRP) in various industries such as transportation, clean energy, and consumer products continues to grow due to its unique properties of high strength, light weight, and chemical resistance. The increased use of CFRP will bring its cost down, as more high volume production factories will be built leading to increasing economies of scale. However, not all of the cost of manufacturing with CFRP is due to the material itself. Arising from its unique properties of mechanical hardness, and chemical resistivity, significant fabrication costs are associated with the manufacturing of CFRP components. See UV Laser Texturing of CFRP for additional information. |

Ultrashort-pulse Laser Structuring

|

Pulse durations of down to a few femtoseconds are available from state of the art laser systems. The high peak intensities provided by ultrashort pulses initiate multiphoton absorption mechanisms, bridging a band gap much larger than the photon energy. Thus, by applying ultrashort pulses the ablation of nearly any material is possible by multiphoton absorption. The non-thermal nature of ultrashort pulsed ablation together with the ultrafast mechanism offers well-defined ablation threshold fluences and enables laser structuring with high precision. See Ultrashort-pulse Laser Structuring for additional information. |