Flat Panel Display Manufacturing

Elevating FPD Manufacturing

Spectra-Physics is a leading supplier of lasers for the manufacture of flat panel displays (FPD) including OLED and LCD. Our lasers are proven in a wide range of FPD applications including glass cutting/drilling, ITO patterning, repair and marking. We deliver a broad portfolio of highly reliable, cost-effective lasers for 24/7 flat panel manufacturing backed by our industry-leading global support organization.

- >1,500 mm/s cutting of tempered glass and other challenging materials

- Enhancing AMOLED and LCD repair with highest precision fs and ns lasers

- Advancing thin film cutting, scribing with optimal cost-performance lasers

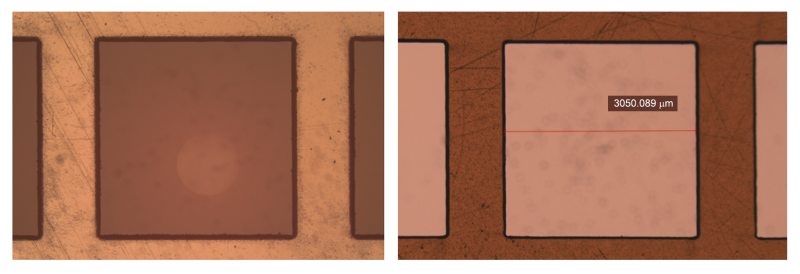

ClearShape™ Industrial Laser Cutting Process

Spectra-Physics introduces ClearShape, a patent-pending femtosecond laser process for highest quality, fast cutting of chemically strengthened glass, unstrengthened glass, and sapphire. At speeds over 1000 mm/sec, the new process results in several-fold improvement in cut quality over other laser processes: no chipping, Ra <0.1 µm edge roughness, and as-cut bending strength of >650 MPa for chemically strengthened glass. Utilizing the widely deployed Spirit® family of industrial femtosecond lasers, the new process is ideal for 24/7 manufacturing of displays and windows for mobile devices, wearables, and other demanding applications.

PI and PET Plastic Processing